Green Initiatives

Recycling for a Sustainable Future

Nylene offers a range of products designed specifically for applications where recycled content is a priority. Our recycled content solutions are engineered to meet the highest standards of quality, performance, and sustainability. They include:

01

Material Innovation

Creating high-performance, eco-friendly products through resource recovery.

02

Closed Loop Systems

Our processes seamlessly collect, process, and reintegrate waste nylon materials.

03

Depolymerization

We specialize in depolymerization to reclaim high-quality nylon 6 from waste.

04

Collaborative Partnerships

We partner with industry peers, waste management, and recycling facilities.

Transforming Waste into Valuable Resources for a Circular Economy

We recognize the importance of recycling to minimize environmental impact and conserve resources. Through strategic initiatives, we turn waste into valuable resources, actively contributing to a circular economy.

Our commitment to sustainability is evident in our development of new materials with recycled content. These materials meet high standards, perform well, and reduce the need for fresh resources.

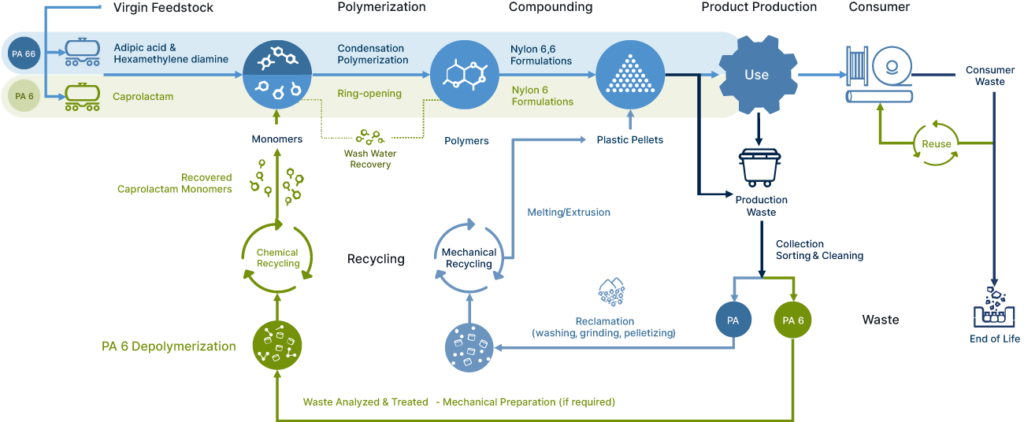

At Nylene, our recycling practices are efficient with closed-loop systems. We seamlessly reuse post-industrial nylon materials, cutting waste and energy use. Our advanced depolymerization process recovers quality nylon 6 from waste, significantly reducing our reliance on new resources and making the nylon industry more environmentally friendly.

Nylon Recycling Through Chemical and Mechanical Processes

Closing the Loop

Sustainable Products & Processes

Nylene offers a range of products designed specifically for applications where recycled content is a priority. Our recycled content solutions are engineered to meet the highest standards of quality, performance, and sustainability. They include:

Resource Recovery Programs

We're dedicated to sustainability through resource recovery programs, creating high-performance, recycled products, reducing virgin resource demand, revolutionizing manufacturing, and realizing cost savings.

Nylon 6 Depolymerization

Our sustainable materials include high-quality nylon 6, recovered through advanced depolymerization, reducing reliance on virgin resources and advancing our mission for a more sustainable nylon industry.

Nylon 6 Depolymerization

Resource Recovery

Chemical Recycling of Nylon 6

Nylene Canada ULC, owns and operates the only process for the recovery, recycling and remanufacture of type six nylon in North America. Through this infrastructure, Nylene diverts quantities of pre-consumer nylon 6 waste away from landfills and incineration facilities

Closed-loop recycling is the most sophisticated form of recycling. This occurs when nylon fibers and plastics are chemically renewed in a depolymerization process and manufactured into a first quality (same as virgin) product again.

Advantages:

By taking nylon 6 back to its chemical raw material form, caprolactam, a true closed-loop process is achieved. This technology allows sustainable renewal of nylon 6 over and over again without loss of properties.

SCS Certifed Depolymeration Process

Through an extensive audit process, we maintains athird party certification for our environmental program from Scientific Certification Services (SCS).

This certification acknowledge our system-wide sustainable practices and manufacturing processes. They attest to our commitment to providing environmentally sensible, sensitive and sustainable products and programs.

Certificate issued for the following Reclamation Process/Program:

Arnprior Nylon-6 Depolymerization Unit

- Has demonstrated 77% yield of caprolactam from processed waste

- Over 2,100,000 kg (dry weight basis) of material is recycled annually

- Capable of processing post-consumer and pre-consumer nylon 6

- Meets the requirements of the SCS Recycling Program Standard

Resource Recovery Programs

Cost Savings, Quality Assurance, and Eco-Friendly Benefits

Nylene’s Resource Recovery program is a specialized closed-loop recycling service designed to help customers save on material costs while reducing their carbon footprint. By taking scrap materials generated by a single customer back into our facility, we’re able to incorporate those recovered resources into future products for that same customer. Through the process of re-compounding, these recovered resources are upgraded into high-quality materials by adding original ingredients that are tailored to enhance the performance of the scrap material.

Why Choose Resource Recovery?

- Nylene’s Resource Recovery program ensures complete and homogeneous blending of materials, unlike on-site blending of regrind or re-pelletized regrind scrap.

- Our team follows strict material handling procedures that adhere to manufacturer specifications to provide our customers with the highest quality materials possible.

- Our Resource Recovery program comes with a certificate of material testing, guaranteeing the quality of the recovered material and providing customers with peace of mind and assurance of top-quality products.

Eco-Friendly Benefits

Aside from cost savings and quality assurance, Nylene’s Resource Recovery program also has environmental benefits. By using recycled materials, our customers can significantly reduce their carbon footprint and promote a sustainable future. This closed-loop recycling program helps to conserve natural resources and minimize waste, leading to a greener and more eco-friendly approach to manufacturing.