High-Performance Solutions

Nylene’s specialized product line for tubing applications

We excel in providing specialized nylon formulations for the tubing industry, drawing on our extensive experience in this field. Our customizable product line features high-performance nylon resins designed to enhance tubing applications. With a focus on durability, flexibility, and chemical resistance, our resins are industry standard.

Our specialized nylon polymers redefine durability, offering unmatched strength, wear resistance, and chemical resilience.

Applications

Nylene Resins for Optimal Tool Performance

Nylene's product line includes modified nylon 6 resins with very good physical properties and excellent extrusion characteristics. We also offer high-viscosity nylon co-polymer with high impact resistance, and optimized resins with good melt strength for high-line speeds in thin wall sections.

Our specialized nylon formulations for the tubing industry offer a wide array of benefits:

- Superior Chemical Resistance: Our nylon resins exhibit excellent resistance to alkalies, oils, greases, and petroleum products. This ensures longevity and reliability, even in environments with challenging substances.

- Water-Resistant and Durable: Unlike some materials that become brittle or swell when exposed to water, our nylon formulations remain stable. This guarantees continued performance, even in wet or humid conditions.

- Fatigue and Vibration Resistant: The exceptional properties of our resins make them resistant to fatigue, tube vibration, and movement. This makes them perfect for applications where stability is paramount.

- Lightweight and Flexible: Our resins are designed to be lightweight without compromising on performance. They boast excellent bend and radii capabilities, allowing for smooth and adaptable installations.

- Crush, Abrasion, and Crack Resistance: Industries requiring materials that can withstand tough conditions can rely on our resins. They exhibit remarkable resistance to crushing, abrasion, and cracking, ensuring longevity even in demanding environments.

Nylon Types Typically used for Heavy Machinery and Construction

Tailored Solutions for the heavy construction industry.

Ideal Uses for Nylon

Our specialized nylon formulations find a diverse range of ideal uses across various industries:

- Automotive, Truck, and Industrial Applications: From fuel lines to hydraulic systems, our nylon resins provide the robustness required for automotive, truck, and industrial applications.

- Aviation Control Panel Wire Harnesses: The reliability and durability of our resins make them a trusted choice for aviation control panel wire harnesses, ensuring consistent performance in critical systems.

- Trailer, Marine, and R.V Manufacturing: In the world of trailers, marine vessels, and recreational vehicles, our resins deliver the toughness needed to withstand outdoor and marine environments.

- Snowmobile and Jet Skis: For recreational vehicles like snowmobiles and jet skis, our resins offer the perfect blend of flexibility and durability to handle varying conditions.

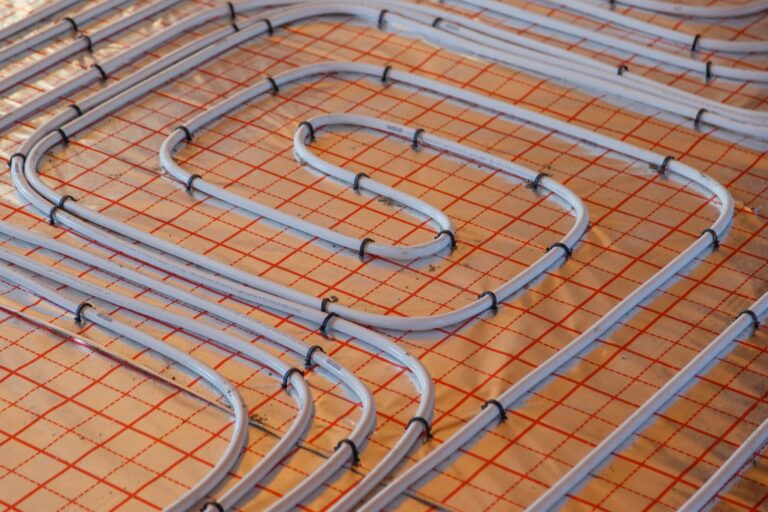

- Agricultural and Construction Machines: In the demanding domains of agriculture and construction, our resins excel in providing the resilience required for heavy-duty machinery and equipment.

Nylon 6

Known for its excellent balance of strength and toughness, Nylon 6 is a versatile choice for tubing applications. It offers exceptional chemical resistance, making it suitable for industries that deal with corrosive substances.

Nylon 66

With a reputation for high mechanical strength and heat resistance, Nylon 6/6 is a go-to option for tubing in demanding environments. Its dimensional stability and resistance to wear make it a preferred choice for industries seeking longevity.

Nylon 12

Nylon 12 stands out for its low moisture absorption and excellent resistance to chemicals and fuels. This makes it a top contender for industries requiring tubing solutions that maintain integrity even when exposed to harsh substances.

Nylon 6/12

Combining the properties of Nylon 6 and Nylon 12, Nylon 6/12 offers a unique balance of flexibility and durability. It's an excellent choice for tubing used in dynamic applications.

Nylene’s product line includes modified nylon 6 resins with very good physical properties and excellent extrusion characteristics. We also offer high viscosity nylon co polymer with high impact resistance, and optimized resins with good melt strength for high line speeds in then wall sections.

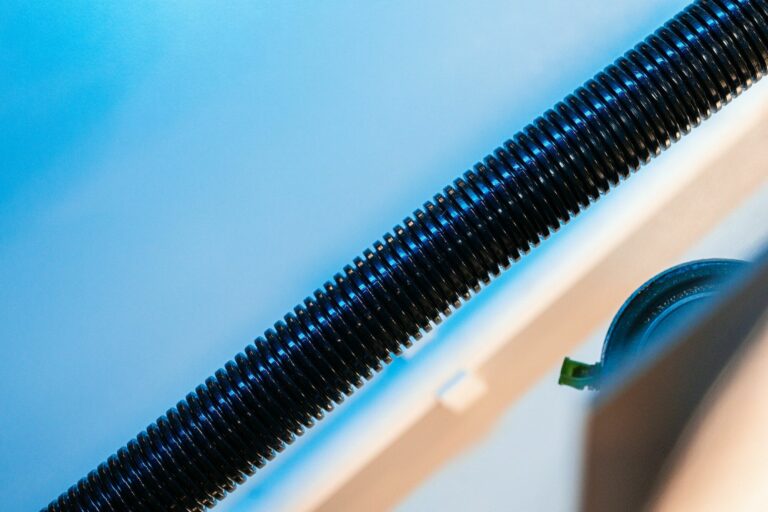

Nylene offers a family of grades designed specifically for the convoluted tubing industry. We also use these resins for other extrusions and molded parts.

Benefits

- Excellent resistance to alkalies, oils, greases and petroleum products.

- Will not become brittle or swell because of water.

- Resistant to fatigue, tube vibration and movement.

- Lightweight and excellent bend and radii.

- Resists crushing, abrasion and cracking.

Ideal Uses

- Automotive, truck and industrial applications

- Aviation control panel wire harnesses

- Trailer, marine and R.V manufacturing

- Snowmobile and jet skis

- Agricultural and construction machines