Nylon Materials for Electric Vehicles

Nylene polymers boast exceptional thermal stability, mechanical strength, and electrical insulating properties, making them an ideal choice for electric vehicles (EVs) critical components such as battery enclosures, connectors, and powertrain elements. With Nylene’s advanced engineering polymers, you can be confident that your EV’s components are built to withstand the rigors of the road.

Nylene’s engineered resins excel in various applications, including fuel, fluid, and chemical tanks, as well as injection and extruded parts.

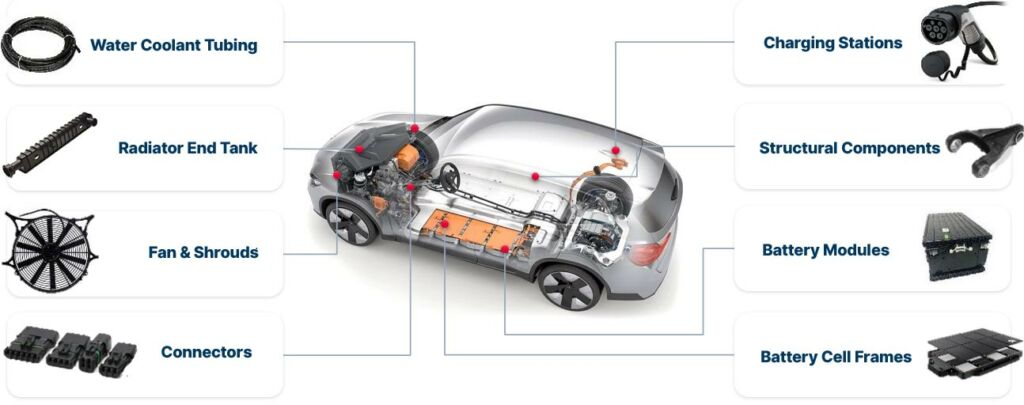

Applications

Nylene Solutions for the EV Market

Nylene, a leading provider of high-performance nylon solutions, offers specialized nylon types to enhance electric vehicle performance and sustainability. With our expertise as a polymer manufacturer, we're ready to address material challenges in EV manufacturing. Our advanced nylon polymer solutions are designed for diverse applications within the EV sector. Below, you'll find Nylene's product offerings that can be customized to meet the dynamic requirements of the EV industry:

- Nylon 6: Nylon 6 is a versatile and widely used material in various industries, including automotive. With its excellent mechanical properties, thermal stability, and electrical insulation, Nylon 6 is well-suited for EV applications. It provides durability and strength to withstand the demanding conditions of electric vehicle components.

- Nylon 6,6: Nylon 6,6 is another type of nylon that offers enhanced properties compared to Nylon 6. It exhibits excellent dimensional stability, high heat resistance, and improved chemical resistance. Nylon 6,6 is commonly used in EV applications that require superior strength, such as structural components and under-the-hood parts.

- Reinforced Nylon Composites: Nylene also offers reinforced nylon composites, which combine the benefits of nylon with the added strength and stiffness of glass fibers or other reinforcing materials. These composites provide increased structural integrity and impact resistance, making them ideal for EV components that require high strength-to-weight ratios.

Nylon Applications for Electric Vehicles

Features of Benefits of Nylon for Electric Vehicles

By incorporating Nylene's nylon solutions into electric vehicle manufacturing, numerous benefits can be achieved:

Enhanced Performance

The high resilience and mechanical properties of Nylene's nylon types ensure superior performance, longevity, and reliability of EV components, contributing to a smooth and efficient driving experience.

Improved Sustainability

Nylon 6 and Nylon 6,6, are manufactured using recycled content, reducing environmental impact. Their durability and recyclability support a circular economy by enabling material reuse at the end of their lifecycle.

Weight Reduction

The lightweight nature of nylon materials helps to reduce the overall weight of EVs, contributing to increased energy efficiency and extended battery life, leading to enhanced range and reduced carbon emissions.

Design Flexibility

Nylene's nylon types offer unlimited styling capabilities and color versatility, allowing automotive designers to create visually appealing and aesthetically pleasing EV interiors and exteriors.

Ease of Maintenance

Nylon's smooth finish is easy-to-clean make it a practical choice for electric vehicles, as it withstands everyday wear and tear, ensuring that the vehicle's appearance remains intact even after prolonged use.

Customizable Solutions

Nylene can help EV manufacturers by providing tailored solutions and expertise in nylon materials, allowing for the customization of properties and characteristics to meet specific requirements.