Nylene provides a wide range of compounds that can be used to protect outdoor equipment from UV damage and corrosion. These compounds often contain special additives for impact resistance, chemical resistance and other specialized needs.

Features & Benefits

Trimmer Line

-

Nylon 6

Nylon 6 Standard Performance for smaller diameter trimmer line

-

Nylon 666

Improved Performance for all diameters with cost advantages over copolymer

-

Nylon 669

Nylon 669 Highest Performance and Best in Practive for all diameters

Flexible & Durable Copolymers for Monofilament Applications

Nylene produces two types of trimmer line, nylon 6 and advanced copolymer grades. The advanced copolymer grades are more durable than ordinary nylon line, making them ideal for cutting medium-heavy vegetation.

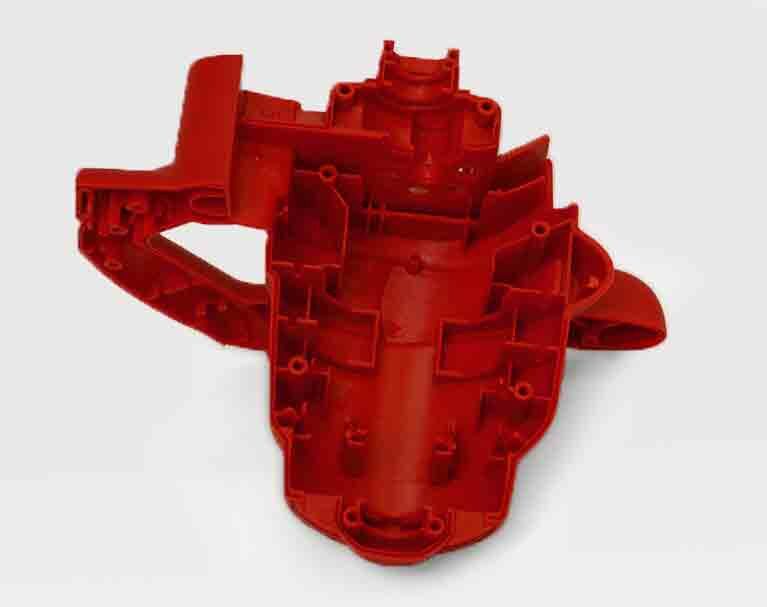

Lawn Care Tools

Available Products

Impact Modified & Glass Reinforced

UV Stabilized & Heat Stabilized Nylon

Prime & Utility Grades with Many Color Options

Injection Molded Parts & Housings

Nylene PA 66 and PA 6 resins provide strength, temperature resistance and chemical resistance to lawn and garden equipment, allowing them to perform under intense conditions and resist fading caused by UV light.

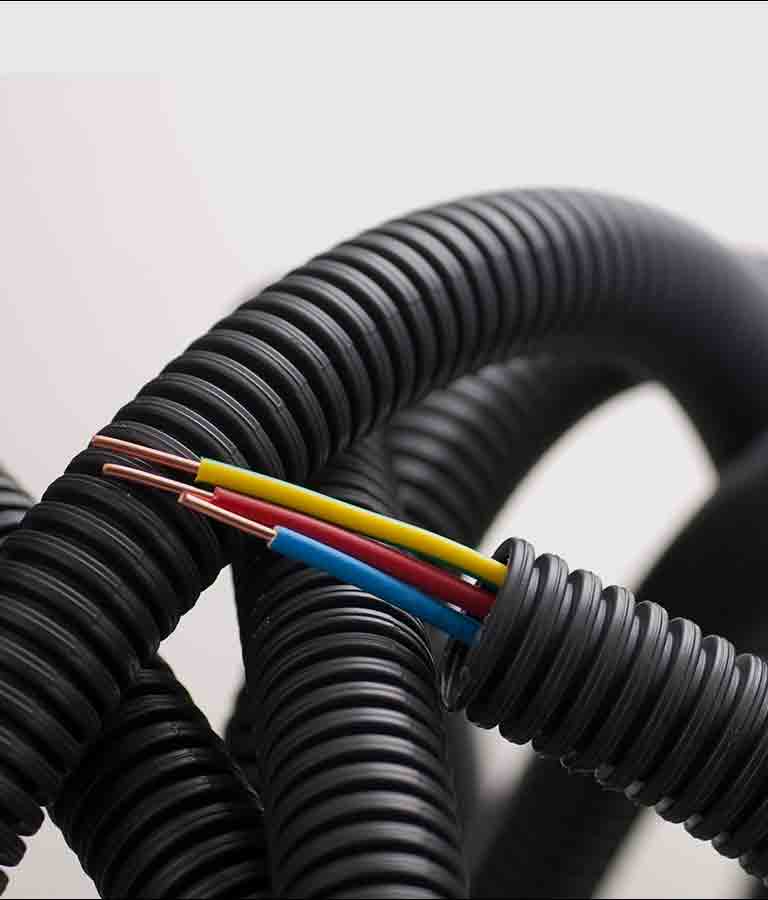

Fuel & Chemical Handling

-

Single & Multi-Layer Systmes

Materials can be use as a single or as part of a multi-layer fuel line and tank systems, reducing failure and scrap

-

Thin Walled Applications

Processors can produce then wall tanks that still meet the EPA and California Air Resources Board (CARB evaporative emission regulations.

Meet Strict Fuel Permeation Requirements

Nylene materials meet strict permeation requirements for fuel related applications in the lawn and garden market. They are the most cost-effective option when it comes to a combination of permeability and mechanical properties.

Solutions

- Nylon 6/69

- Extrusion Grade

- Nylene PAC900-120UNL is a high viscosity copolymer of nylon 6 and 6,9.

- PAC900-120UNL has many of the properties desirable in nylon 6 coupled with the advantages of a copolymer, which include lower processing temperatures.

- Nylon 6

- Extrusion Grade

- Nylene PAC900-120U is a high viscosity copolymer of nylon 6 and 6,9.

- PAC900-120U has many of the properties desirable in nylon 6 coupled with the advantages of a copolymer, which include lower processing temperatures.

- Nylon 6/69

- Extrusion Grade

- Nylene® CP41321U is a nylon copolymer.

- Nylene CP41321U has many of the properties desirable in nylon such as toughness, chemical resistance and strength coupled with the advantages of a copolymer.

- These advantages include high elongation, good clarity and flexibility, and lower processing temperatures.

- CP41321U is unextracted, utilizing the monomer as a plasticizer for increased flexibility.

- Nylon 6

- Unfilled

- Extrusion Grade

- Cylinder temperatures should be in the 435 – 525ºF range.

- Designed for excellent cold temperature impact.

- High impact modified nylon 6 suitable for both molding and extrusion.

- Parts molded from 743 have excellent impact strength right out of the mold without post conditioning.

- Outstanding high strength and high cold temperature impact.

- Nylon 6

- Rotational Molding Grade

- Specially formulated, heat stabilized, nylon powder for the ROTOMOLDING process

- Chemical resistance to aromatic solvents, etc. especially at elevated temperatures

- Custom colors on demand

- Higher heat resistance and melting point. Not as likely to melt or lose shape if left in the sun.

- Higher impact at room and elevated temperatures

- Meets the strict CARB and EPA fuel permeation regulations

- Permits a single step process and a single layer material fuel tank. This will reduce the chances of failure and scrap, which makes it extremely cost competitive

- Nylon 6

- Heat Stabilizer

- Rotational Molding Grade

- Engineered nylon 6 compound optimized for Rotational Molding

- Heat stabilization for high-temperature performance

- Economical formulation minimizes costs compared to 100% powder

- Optimized for use alongside Nylene® 494P BLK powder to ensure good part quality

- Compliant with CARB and EPA fuel permeation regulations, prioritizing environmental sustainability

- Nylon 6/6

- Glass Filled

- Injection Molding Grade

- Nylene 4114-33 GL HS is a compounded, heat-stabilized, impact-modified, 33% glass fiber-reinforced nylon 6/6 molding resin with excellent impact strength.

- Nylon 6/6

- Impact Modified

- Glass Filled

- Nylene 4114-33 is a compounded, impact-modified, 33% glass fiber-reinforced nylon 6/6 molding resin with excellent impact strength.

- Nylon 6/6

- Glass Filled

- Nylene 4114-14 HSL is a glass fiber reinforced, impact modified, heat stabilized nylon 6/6.

- Nylene 4114-14 HSL has improved strength and stiffness over un-reinforced nylons, and improved impact resistance over typical reinforced grades, especially in dry conditions.

- Nylon 6/6

- Impact Modified

- Glass Filled

- Nylene 4114-14 is an impact-modified molding resin with excellent impact strength.