Specialty Nylon for Tough Applications

Enhancing Heavy Machinery Performance & Reliability

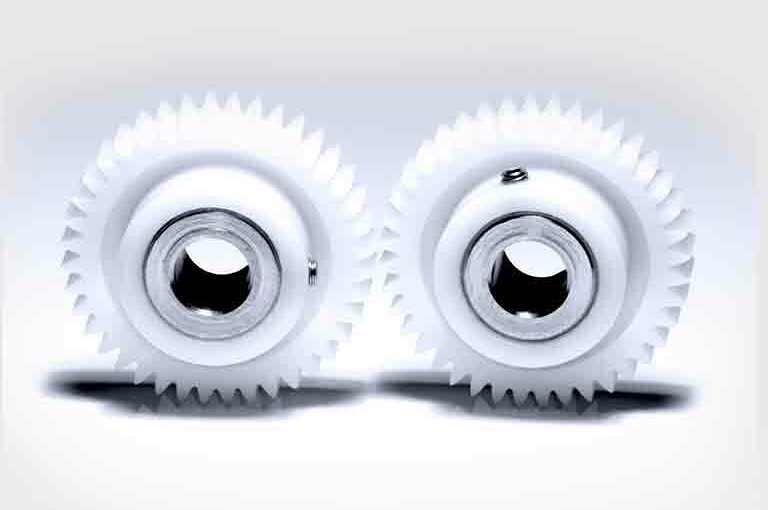

In the dynamic realm of heavy machinery and construction, nylon material stands out for its unparalleled strength and adaptability. As a specialty nylon manufacturer, Nylene offers an extensive range of engineered nylon types engineered to meet the most challenging industrial environments.

Our specialized nylon polymers redefine durability, offering unmatched strength, wear resistance, and chemical resilience.

Applications

Nylene Resins for Optimal Tool Performance

Recognizing the unique requirements of the heavy machinery and construction industry, Nylene provides a range of customization capabilities. Our experts collaborate closely with customers to develop tailored nylon solutions, taking into account specific application needs, performance goals, and regulatory standards. Whether it's material formulation, color options, or additional additives, we ensure that our nylon solutions align precisely with your requirements.

Features and Benefits of Nylon

- Superior Strength and Durability: Nylene's nylon resins provide exceptional strength and durability, ensuring optimal performance and longevity of heavy machinery and construction equipment. They can withstand heavy loads, extreme temperatures, and challenging working conditions, minimizing downtime and maintenance costs.

- Excellent Wear and Abrasion Resistance: Our nylon materials exhibit excellent wear and abrasion resistance, making them ideal for high-stress applications in heavy machinery. They can withstand the rigors of constant friction and impact, prolonging the lifespan of critical components and reducing the need for frequent replacements.

- Chemical Resistance: Nylene's nylon resins offer excellent chemical resistance, protecting heavy machinery and construction equipment from corrosive substances, oils, and fuels. This ensures reliable performance even in harsh chemical environments, enhancing the overall durability and longevity of the machinery.

- Noise and Vibration Dampening: Nylon's inherent properties enable it to effectively dampen noise and vibrations in heavy machinery and construction equipment. This contributes to a quieter and more comfortable working environment while reducing wear and tear on components.

Nylon Types Typically used for Heavy Machinery and Construction

Tailored Solutions for the heavy construction industry.

Nylon 66

With its outstanding mechanical properties, Nylon 6/6 is widely used in heavy machinery and construction equipment. With its exceptional strength, toughness, and impact resistance.

Applications: gears, bearings, pulleys, and conveyor belts

Nylon 12

Valued for its excellent weather resistance and flexibility, Nylon 12 finds extensive use in construction and heavy machinery. Choose Nylon 12 for its durability and protection against harsh environmental conditions.

Applications: hydraulic seals, bushings, cable ties, and protective covers

Glass-Filled Nylon

Nylene provides glass-filled nylon composites that combine the strength and stiffness of nylon with the added reinforcement of glass fibers. These materials are commonly utilized in applications where high strength and dimensional stability are crucial.

Applications: machine housings, structural components, and heavy-duty parts