Elevating Tool Performance

Leveraging Nylon 6/6’s Exceptional Mechanical, Thermal, and Chemical Properties

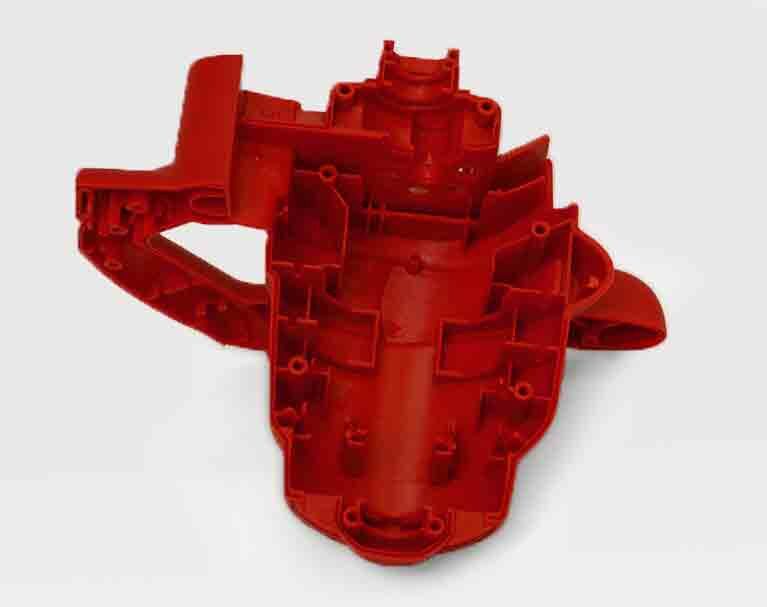

We specialize in polymer engineering and have a deep understanding of the crucial role Nylon 6/6 plays in power tools. With its strong tensile strength, unmatched fracture toughness, and exceptional impact resistance, Nylon 6/6 is the ideal choice for overcoming challenges in power tool part manufacturing and design.

Nylene’s Nylon 6/6 resins can be precisely customized to meet the demands of both power and hand tools, enhancing performance and enabling precision tasks. Their inherent toughness ensures resilience even under the most demanding conditions, resulting in material strength that translates into functional excellence.

The suitability of Nylon 6,6 for various parts in tool applications is further enhanced by its dimensional stability, chemical resistance, and thermal stability.

Applications

Nylene Resins for Optimal Tool Performance

Nylene empowers power tool manufacturers to create products that perfectly align with their specifications, performance needs, and branding. Our customized nylon resins enable the development of power tools that excel in performance, durability, and reliability across various applications.

Customizations for Your Power Tool Parts

Tailored Solutions for Precision Power Tool Components from Nylene

Tailored Properties

Nylene offers the ability to customize the properties of Nylon 6/6 resins to meet specific requirements of power tool applications. This includes tailoring the material's mechanical strength, impact resistance, flexibility, and other relevant characteristics.

Color Matching

Our custom color matching services ensure the nylon materials align with the desired aesthetics and branding of the appliances.

Additive Incorporation

Nylene can incorporate various additives into the nylon resin to enhance specific properties or address specific needs of power tools. This includes additives for improved lubricity, flame retardancy, UV resistance, or anti-static properties.

Reinforcement Options

Nylene offers options for reinforcing the nylon resin with various fillers or fibers, such as glass fibers or mineral fillers. This can enhance the material's mechanical properties, such as increased strength, stiffness, and dimensional stability, making it suitable for demanding power tool applications.

Surface Modifications

Nylene can modify the surface characteristics of the nylon resin to meet specific requirements, such as improving its wear resistance, reducing friction, or enhancing its compatibility with other materials used in power tool assemblies.

Processing Assistance

Nylene provides technical support and expertise to optimize the processing of nylon resins in power tool manufacturing. This includes guidance on injection molding parameters, tool design considerations, and processing techniques to ensure efficient and high-quality production.

Recommendations

- Copolymer, Nylon 6/69

- Heat Stabilizer

- Rotational Molding Grade

- Rotational Molding Engineered, High Impact Resistance, Heat Stabilized, Nylon Copolymer

- CARB and EPA Fuel Permeation Regulation Compliant

- Nylon 6/12

- Blow Molding Grade

- 6207HS BK is specifically designed for extrusion but can also be used for blow molding and some molded parts

- High viscosity, 6/12 nylon with high impact resistance and superior flexibility

- Optimized with good melt strength for high line speeds in thin wall sections

- Very good physical properties and excellent extrusion characteristics to support extrusion of very complex profiles.

- Nylon 6

- Heat Stabilizer

- Glass Filled

- Injection Molding Grade

- Glass fiber reinforced, heat stabilized, nylon 6 injection molding resin

- Suitable for end uses requiring high stiffness along with good appearance

- Heat and chemical resistance typical of nylon 6 resins, while glass fiber reinforcement provides outstanding strength and stiffness

- The nylon 6 base resin provides excellent surface appearance

- Nylon 6

- Heat Stabilizer

- Glass Filled

- Injection Molding Grade

- Glass fiber reinforced, heat stabilized, nylon 6 injection molding resin

- Suitable for end uses requiring high stiffness along with good appearance

- The nylon 6 base resin provides excellent surface appearance

- Heat and chemical resistance typical of nylon 6 resins, while glass fiber reinforcement provides outstanding strength and stiffness

- Nylon 6

- Glass Filled

- Injection Molding Grade

- Glass fiber reinforced nylon 6 featuring high tensile strength, stiffness and impact resistance

- Nylon 6

- Heat Stabilizer

- Glass Filled

- Glass fiber reinforced heat stabilized nylon 6 injection molding resin.

- High heat and chemical resistance inherent in nylon type resins, along with higher strength and stiffness due to glass fiber reinforcement.

- Excellent surface appearance when processed in a warm mold.

- Nylon 6

- Glass Filled

- Injection Molding Grade

- Nylene 5215 is a glass fiber-reinforced nylon featuring high tensile strength and stiffness.

- Nylon 6

- Glass Filled

- Injection Molding Grade

- Glass fiber reinforced nylon 6

- Heat and chemical resistance and excellent surface appearance associated with nylon 6 resins

- Improved strength and stiffness properties over unreinforced nylon

- Nylon 6

- Heat Stabilizer

- Glass Filled

- Injection Molding Grade

- Glass fiber reinforced, heat-stabilized nylon 6

- Heat and chemical resistance and excellent surface appearance associated with nylon 6 resins

- Improved strength and stiffness properties over unreinforced nylon

- Nylon 6

- Glass Filled

- Injection Molding Grade

- Nylene 5213 is a glass fiber-reinforced nylon featuring high tensile strength and stiffness.